Copper plated zinc

Home » Science Education » Copper plated zincCopper plated zinc

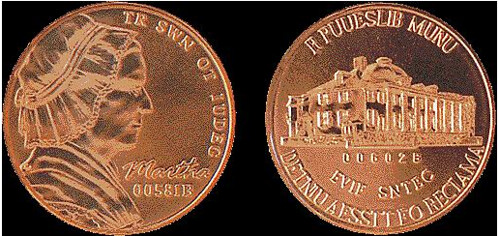

Copper Plated Zinc. Technically zinc plating on copper is not a problem. Since you are currently using cyanide based copper plating baths you are familiar with one of the plating baths required. The copper plated zinc cent coins are still being produced today. A standard process for plating copper on zinc alloys is as follows.

Copper Plating Onto Zinc Charrette Beget From maxpierson.me

Copper Plating Onto Zinc Charrette Beget From maxpierson.me

Conventional procedure for electrolytically plating copper on zinc or its alloys particularly zinc die casting generally includes first treating the zinc or zinc die casting in an electroplating solution generally termed a copper strike solution e g containing copper cyanide then treating the zinc or zinc alloy part in a bright acid copper electroplating bath to form a copper electroplate the part then usually being treated in an electroplating nickel bath followed by treatment in a. They are composed of an inner core alloy of 99 2 zinc and 0 8 copper with an outer plating of pure copper for an overall composition of 97 5 zinc and 2 5 copper and are minted on blanks produced for the mint by an outside manufacturer jarden zinc products. A standard process for plating copper on zinc alloys is as follows. Since you are currently using cyanide based copper plating baths you are familiar with one of the plating baths required. Connecting the positive lead to the zinc electrode removes electrons form the zinc electrode. Solution for the zinc in a copper plated penny will dissolve in hydrochloric acid if the copper coating is filed down in several spots so that the hydrochloric.

Connecting the positive lead to the zinc electrode removes electrons form the zinc electrode.

The zn atoms form zn 2 ions zn s zn 2 aq 2e. Their composition adopted to cut production costs provided only a short term. Cents had been struck on copper plated zinc planchets since 1982 earning the coins the moniker zincoln. The copper plated zinc cent coins are still being produced today. However diffusion of the zinc into the copper will occur. Solution for the zinc in a copper plated penny will dissolve in hydrochloric acid if the copper coating is filed down in several spots so that the hydrochloric.

Source: error-ref.com

Source: error-ref.com

In the picture below you can see the bubbles of hydrogen gas coming off the zinc plate. Actually the plating of zinc alloys is fairly straightforward. The acid just attacked the zinc and i got a lot of bubbling and soot deposits but no copper. The copper plated zinc cent coins are still being produced today. They are composed of an inner core alloy of 99 2 zinc and 0 8 copper with an outer plating of pure copper for an overall composition of 97 5 zinc and 2 5 copper and are minted on blanks produced for the mint by an outside manufacturer jarden zinc products.

Source: usacoinbook.com

Source: usacoinbook.com

A standard process for plating copper on zinc alloys is as follows. If the zinc plating is not of sufficient thickness it may seem to disappear. The copper plated zinc cent coins are still being produced today. The zinc atoms are platted out as metallic zinc zn 2 aq 2e zn s on the copper electrode. Their composition adopted to cut production costs provided only a short term.

Source: ebay.co.uk

Source: ebay.co.uk

They are composed of an inner core alloy of 99 2 zinc and 0 8 copper with an outer plating of pure copper for an overall composition of 97 5 zinc and 2 5 copper and are minted on blanks produced for the mint by an outside manufacturer jarden zinc products. Obviously the resultant material at the interface of the zinc and copper and after migration will be brass. The zn atoms form zn 2 ions zn s zn 2 aq 2e. The zinc atoms are platted out as metallic zinc zn 2 aq 2e zn s on the copper electrode. The copper plated zinc cent coins are still being produced today.

Source: coinbooks.org

Source: coinbooks.org

If the zinc plating is not of sufficient thickness it may seem to disappear. The process works pretty well for plating copper or zinc onto steel but i was completely unsuccessful at plating copper onto zinc. If the zinc plating is not of sufficient thickness it may seem to disappear. The acid just attacked the zinc and i got a lot of bubbling and soot deposits but no copper. A standard process for plating copper on zinc alloys is as follows.

Source: sciencewithscreens.blogspot.com

Electroclean cathodically direct or forward. Solution for the zinc in a copper plated penny will dissolve in hydrochloric acid if the copper coating is filed down in several spots so that the hydrochloric. Electroclean cathodically direct or forward. Connecting the positive lead to the zinc electrode removes electrons form the zinc electrode. They are composed of an inner core alloy of 99 2 zinc and 0 8 copper with an outer plating of pure copper for an overall composition of 97 5 zinc and 2 5 copper and are minted on blanks produced for the mint by an outside manufacturer jarden zinc products.

Source: coinbooks.org

Source: coinbooks.org

However diffusion of the zinc into the copper will occur. Conventional procedure for electrolytically plating copper on zinc or its alloys particularly zinc die casting generally includes first treating the zinc or zinc die casting in an electroplating solution generally termed a copper strike solution e g containing copper cyanide then treating the zinc or zinc alloy part in a bright acid copper electroplating bath to form a copper electroplate the part then usually being treated in an electroplating nickel bath followed by treatment in a. Their composition adopted to cut production costs provided only a short term. The zn 2 ions in solution near the copper electrode gain electrons to form zinc atoms. Except for the new lighter total coin weight of 2 5 grams each these newer coins are identical in diameter and thickness and nearly in appearance to the mostly.

Source: vcoins.com

Source: vcoins.com

However diffusion of the zinc into the copper will occur. The zn atoms form zn 2 ions zn s zn 2 aq 2e. The copper plated zinc cent coins are still being produced today. Except for the new lighter total coin weight of 2 5 grams each these newer coins are identical in diameter and thickness and nearly in appearance to the mostly. Obviously the resultant material at the interface of the zinc and copper and after migration will be brass.

Source: collectons.com

Source: collectons.com

The zn atoms form zn 2 ions zn s zn 2 aq 2e. Solution for the zinc in a copper plated penny will dissolve in hydrochloric acid if the copper coating is filed down in several spots so that the hydrochloric. The acid just attacked the zinc and i got a lot of bubbling and soot deposits but no copper. Technically zinc plating on copper is not a problem. The zn 2 ions in solution near the copper electrode gain electrons to form zinc atoms.

Source: chemdemos.uoregon.edu

However diffusion of the zinc into the copper will occur. The copper plated zinc cent coins are still being produced today. If the zinc plating is not of sufficient thickness it may seem to disappear. However diffusion of the zinc into the copper will occur. Cents had been struck on copper plated zinc planchets since 1982 earning the coins the moniker zincoln.

Source: thesprucecrafts.com

Source: thesprucecrafts.com

However diffusion of the zinc into the copper will occur. Their composition adopted to cut production costs provided only a short term. They are composed of an inner core alloy of 99 2 zinc and 0 8 copper with an outer plating of pure copper for an overall composition of 97 5 zinc and 2 5 copper and are minted on blanks produced for the mint by an outside manufacturer jarden zinc products. Technically zinc plating on copper is not a problem. Conventional procedure for electrolytically plating copper on zinc or its alloys particularly zinc die casting generally includes first treating the zinc or zinc die casting in an electroplating solution generally termed a copper strike solution e g containing copper cyanide then treating the zinc or zinc alloy part in a bright acid copper electroplating bath to form a copper electroplate the part then usually being treated in an electroplating nickel bath followed by treatment in a.

Source: treasurenet.com

Obviously the resultant material at the interface of the zinc and copper and after migration will be brass. The zn 2 ions in solution near the copper electrode gain electrons to form zinc atoms. Since you are currently using cyanide based copper plating baths you are familiar with one of the plating baths required. Conventional procedure for electrolytically plating copper on zinc or its alloys particularly zinc die casting generally includes first treating the zinc or zinc die casting in an electroplating solution generally termed a copper strike solution e g containing copper cyanide then treating the zinc or zinc alloy part in a bright acid copper electroplating bath to form a copper electroplate the part then usually being treated in an electroplating nickel bath followed by treatment in a. Obviously the resultant material at the interface of the zinc and copper and after migration will be brass.

Source: youtube.com

Source: youtube.com

Connecting the positive lead to the zinc electrode removes electrons form the zinc electrode. The zn atoms form zn 2 ions zn s zn 2 aq 2e. Electroclean cathodically direct or forward. In the picture below you can see the bubbles of hydrogen gas coming off the zinc plate. Actually the plating of zinc alloys is fairly straightforward.

Source: maxpierson.me

Source: maxpierson.me

The acid just attacked the zinc and i got a lot of bubbling and soot deposits but no copper. The zinc atoms are platted out as metallic zinc zn 2 aq 2e zn s on the copper electrode. In the picture below you can see the bubbles of hydrogen gas coming off the zinc plate. Actually the plating of zinc alloys is fairly straightforward. The zn 2 ions in solution near the copper electrode gain electrons to form zinc atoms.

Source: ngccoin.com

Source: ngccoin.com

In the picture below you can see the bubbles of hydrogen gas coming off the zinc plate. Technically zinc plating on copper is not a problem. Except for the new lighter total coin weight of 2 5 grams each these newer coins are identical in diameter and thickness and nearly in appearance to the mostly. The zinc atoms are platted out as metallic zinc zn 2 aq 2e zn s on the copper electrode. The zn 2 ions in solution near the copper electrode gain electrons to form zinc atoms.

Source: ebay.co.uk

The acid just attacked the zinc and i got a lot of bubbling and soot deposits but no copper. Except for the new lighter total coin weight of 2 5 grams each these newer coins are identical in diameter and thickness and nearly in appearance to the mostly. Cents had been struck on copper plated zinc planchets since 1982 earning the coins the moniker zincoln. Obviously the resultant material at the interface of the zinc and copper and after migration will be brass. If the zinc plating is not of sufficient thickness it may seem to disappear.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title copper plated zinc by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.